- Home Page

- Company Profile

-

Our Products

- Swimming Pool

- Water Park

- Swimming Pool Filters

- Swimming Pool Pumps

- Swimming Pool Fittings

- Swimming Pool Cleaning Equipment

- Swimming Pool Accessories

- Swimming Pool Disinfection System

- Swimming Pool Underwater Lights

- Health Club Equipments

- Outdoor Fountains

- Effluent & Sewage Treatment Plants

- Swimming Pool Chemicals

- Our Clients

- Contact Us

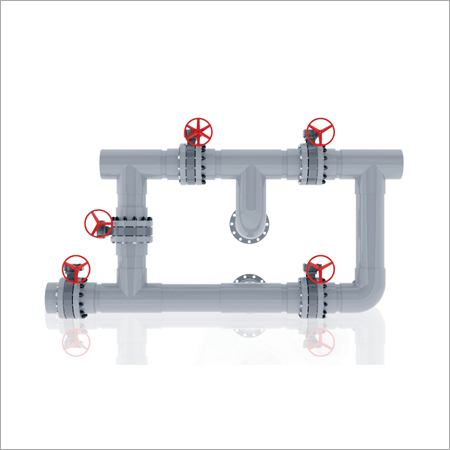

Five Way Butterfly Valve

Product Details:

- Operating Temperature -10C to 110C

- Mount Type Flanged

- Flow Rate Variable, depends on pipeline

- Equipment Type Industrial Valve

- Control Type Lever / Gear Operated

- Type Butterfly Valve

- Application Chemical, Water, Power Plants

- Click to View more

X

Five Way Butterfly Valve Product Specifications

- Chemical, Water, Power Plants

- Variable, depends on pipeline

- Butterfly Valve

- Industrial Valve

- Flow Direction Control

- Five-way

- Lever / Gear Operated

- DN50 to DN300

- Blue

- -10C to 110C

- Manual

- Cast Iron

- Flanged

Product Description

Five Way Butterfly Valve is designed with a pipe assembly having 5 valves separately installed in system, which is used in pools and water parks to control pressure & flow of water according to need and requirement. It is made with great precision using excellent quality of components under vigilance of our trusted engineers. We offer Five Way Butterfly Valve in customizable configurations at reasonable prices as demanded by the customer. It is known to be a cost effective solution of supplying water at high pressure.

Features:

-

Corrosion resistant structure

-

Robust construction

-

Requires low maintenance

Five Way Butterfly Valve

Emaux Commercial Swimming Pool Filters Bobin wound made of Fibre Glass and UV-resistance surface that allows filter to be installed under direct sunlight. Comes with automatic air release system, laterals with fine gaps to keep out filter media and dirt particles with an option of sight glass and manhole.

- Working Pressure : 2.5 bar or 4.0 bar

- Test Pressure : 6 bar

- Filtration Velocity : Upto 50 cu.m./hr./sq.m.

Versatile Five-Way Flow Management

This butterfly valve is uniquely designed with five ports, making it ideal for complex piping systems needing multi-directional control. Whether for diverting, mixing, or isolating flows, the valves five-way design simplifies pipeline layouts and minimizes installation costs.

Superior Sealing and Leakage Protection

With sealing options in EPDM, PTFE, or NBR, and leakage class VI (Bubble-Tight), the valve guarantees tight shutoff even under demanding conditions. It is constructed to meet ISO 5752 and API 609 standards for reliable, high-integrity sealing in industrial piping systems.

Durable Construction for Industrial Demands

Built from cast iron with a choice of stainless steel or ductile iron discs and stainless steel shaft, this valve endures rigorous operation in chemical, water, and power plants. The robust epoxy coating or painting provides exceptional corrosion resistance for longevity.

FAQs of Five Way Butterfly Valve:

Q: How does a five-way butterfly valve control flow direction in pipelines?

A: A five-way butterfly valve allows operators to direct the flow of liquids, gases, or slurries between multiple pipeline branches, enabling mixing, diversion, or isolation as needed within a single compact valve assembly.Q: What sealing materials are available for the five-way butterfly valve and which media are they suitable for?

A: Available seal materials include EPDM, PTFE, and NBR. EPDM is ideal for water and mild chemicals, PTFE for aggressive chemicals, and NBR for oils and hydrocarbons, providing compatibility with a wide range of process media.Q: When should I choose a flanged end connection for this valve?

A: Flanged end connections, compliant with ANSI, DIN, and BS standards, are suitable when secure, high-integrity jointing is required for industrial pipelines, especially in chemical, water, and power plant installations.Q: Where can the five-way butterfly valve be installed?

A: This valve is designed for installation in industrial facilities, including chemical plants, water treatment stations, and power plants, wherever complex flow routing and reliable valve performance are needed.Q: What is the process for actuating the five-way butterfly valve?

A: The valve can be manually operated via lever or gear, or automated using pneumatic or electric actuators for remote or precise flow control, depending on process requirements and system automation level.Q: What are the main benefits of using this five-way butterfly valve in industrial applications?

A: Key benefits include compact design for multiple flow paths, bubble-tight sealing for zero leakage, robust corrosion resistance, and compatibility with diverse process fluids, all supporting streamlined flow management and operational efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Swimming Pool Filters' category

|

NOVATECH ENVIRO SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Call Me Free

Call Me Free